In the contemporary era of rapid industrial automation, Supervisor from a precision instrument manufacturing firm confronts a persistent challenge. Traditional commercial monitors deployed on the production line are succumbing to frequent failures. The root cause? The unforgiving environment rife with vibrations and dust. These breakdowns not only trigger accidental shutdowns due to false touches but also inflict substantial financial losses, tallying up to hundreds of thousands of yuan monthly. However, a revolutionary solution has emerged: the industrial tablet PC touch screen P10J, powered by the N5100 processor. It's revolutionizing the benchmarks of human-machine interaction device reliability within industrial setups.

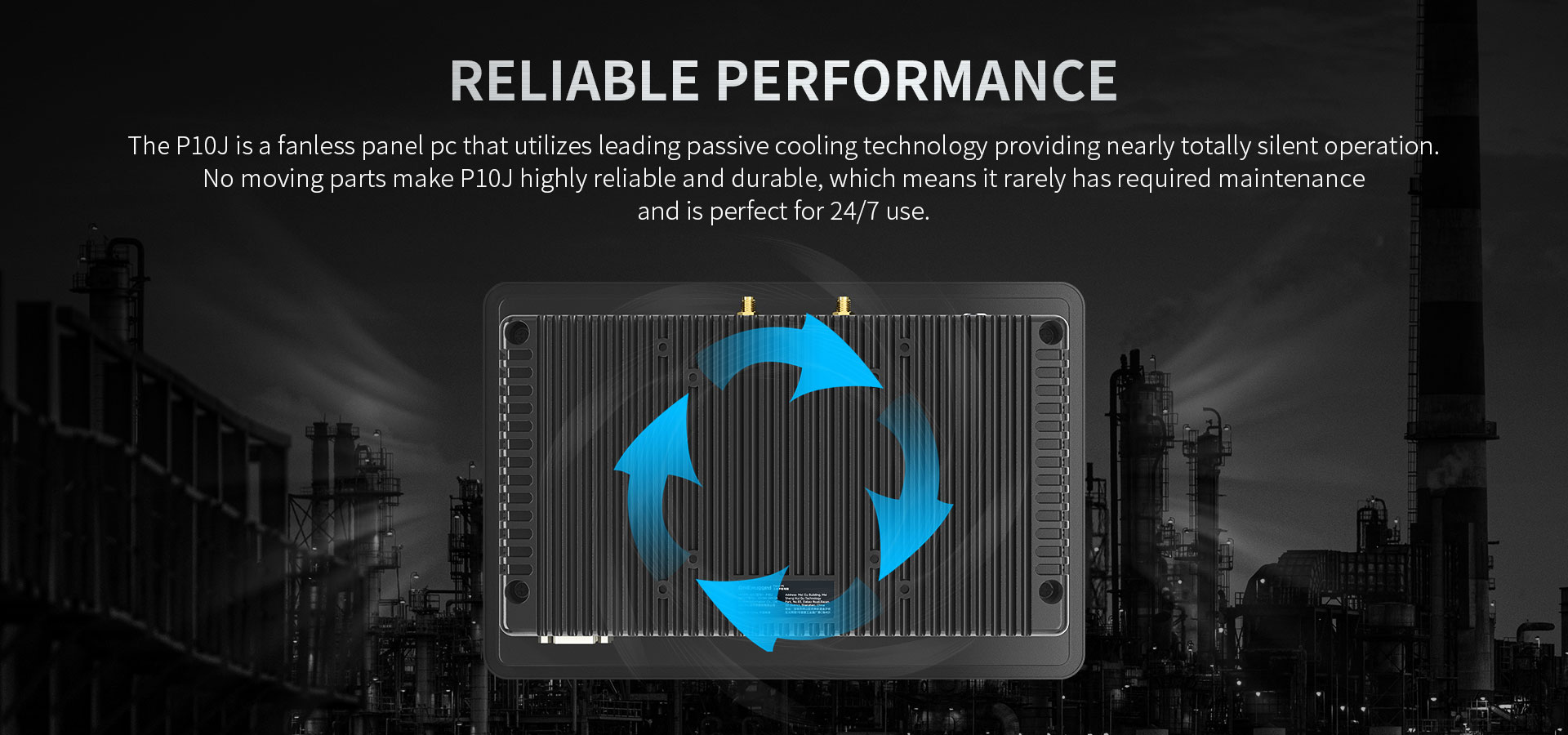

Industrial monitors, often regarded as the pivotal "digital nerve centers" in the Industry 4.0 epoch, hold the key to transforming intricate machine data into comprehensible and actionable interfaces. This is precisely where industrial panel PC Windows 11 devices truly excel. The P10J distinguishes itself with its hermetically sealed fanless design and extensive heat dissipation fins. This innovative construction effectively eradicates the system crash issues that plague traditional devices, typically caused by dust infiltrating the cooling vents. In Supervisor's workshop, this tablet industrial Windows 11 solution operates continuously for 18 hours daily, efficiently processing PLC control commands. Its capacity to function flawlessly across a wide temperature spectrum, ranging from -20°C to 60°C, enables it to effortlessly endure the significant 30°C temperature fluctuations between winter and summer. Moreover, boasting an IP65 protection rating, the industrial tablet PC touch screen remains operational even during high-pressure water gun equipment washes.

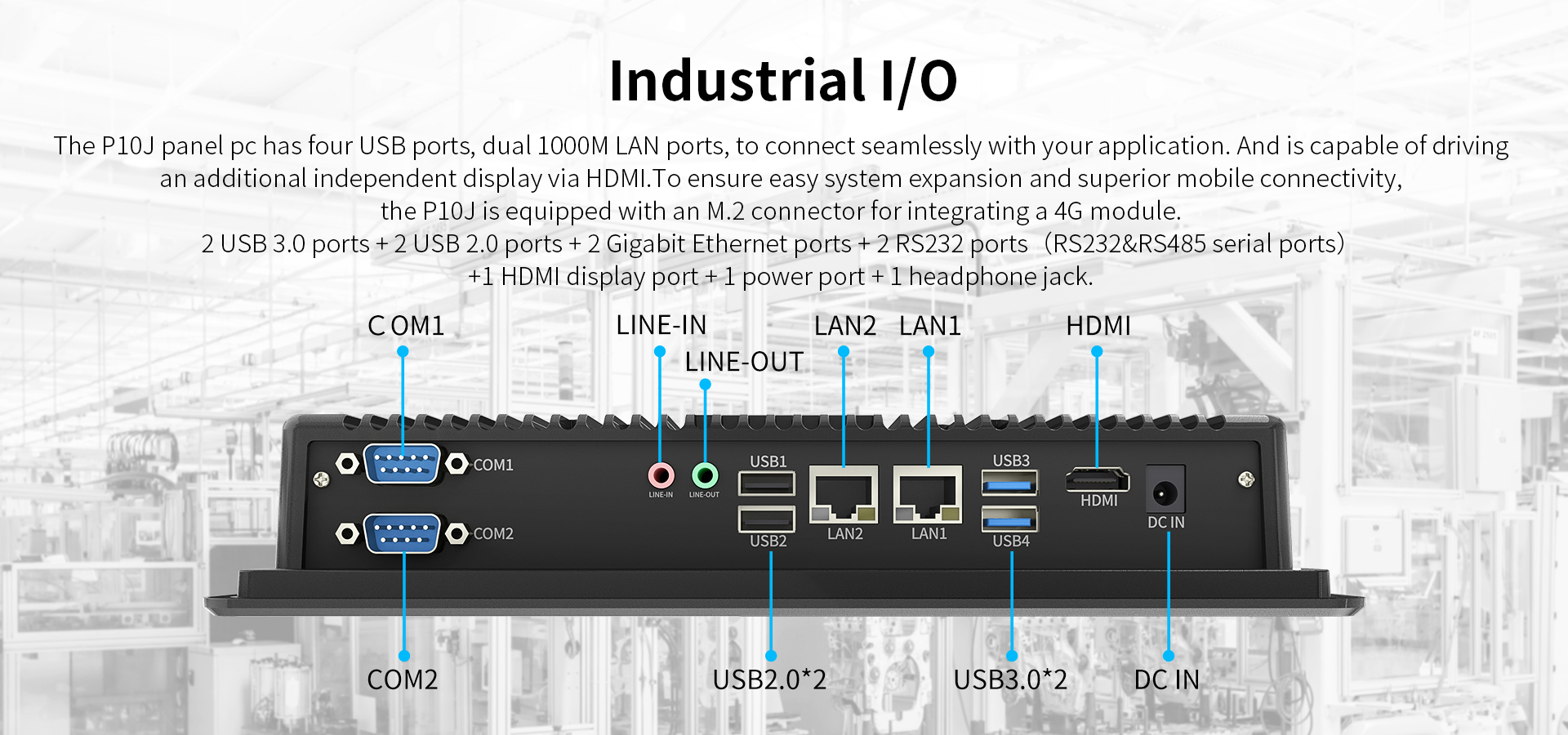

When the company clinched an urgent order from a major multinational enterprise, the industrial panel PC Windows 11's modular expansion capabilities emerged as a game-changing factor. By integrating a 4G module through the built-in M.2 interface, the device can still relay production data in real-time, even in workshop areas with weak or non-existent wireless network coverage. The dual RJ45 interfaces, complemented by the switchable RS232/485 serial ports, facilitate the simultaneous connection of multiple detection devices with diverse protocols. This streamlines the quality inspection process, reducing the manpower requirement from three workers to just one. Adding to its array of remarkable features, the P10J's 700cd/m² high-brightness industrial tablet PC touch screen guarantees clarity even under direct sunlight streaming from the factory ceiling. Paired with 10-point capacitive touch technology, workers can operate the control system with pinpoint accuracy, even while wearing gloves.

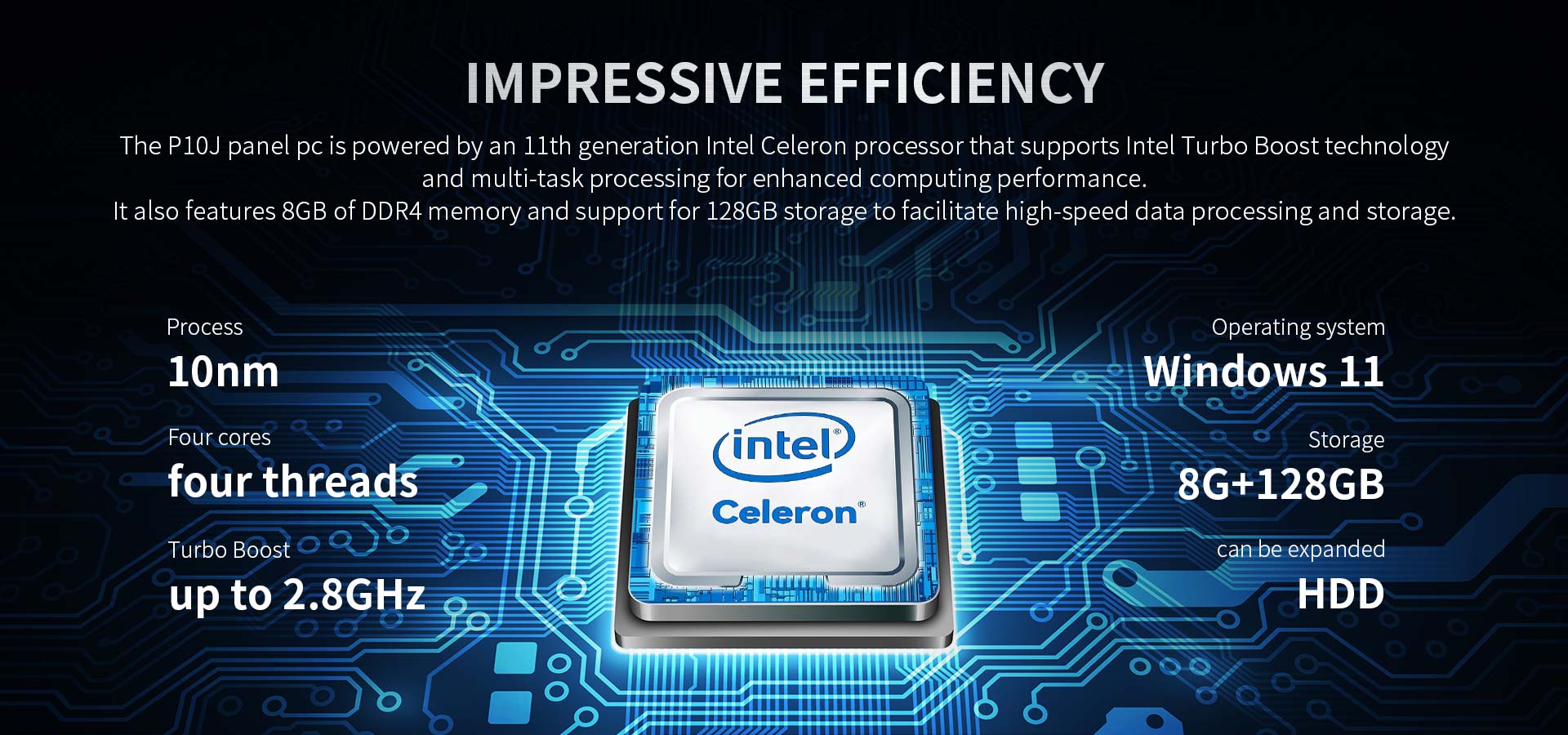

As a tablet industrial Windows 11 device, the P10J harnesses the advanced attributes of this operating system. Over a six-month usage span, the industrial panel PC Windows 11's anti-electromagnetic interference design effectively defends against the electromagnetic pulses generated by high-power motors in the workshop. Its ±15kV air discharge protection further shields the delicate circuit boards from static electricity damage. The Windows 11 Professional Edition installed on the device enables seamless unified management of multiple production line terminals via group policies. Additionally, the DC 12-24V wide voltage input characteristic ensures stable operation, despite frequent voltage fluctuations in the workshop. Collectively, these features have significantly enhanced the device's reliability, slashing the failure rate from seven times a month to zero.

This success narrative is far from isolated. A food packaging machinery manufacturer capitalized on the P10J's impact-resistant panel and anti-condensation design to achieve around-the-clock monitoring in a frigid -15°C cold storage environment. Meanwhile, a chemical company exploited the industrial panel PC Windows 11's USB 3.0 high-speed transmission interface to swiftly transfer real-time image data from hazardous areas to the central control room. These practical implementations underscore the true essence of tablet industrial Windows 11 devices. They are not merely information-displaying devices; they are the indispensable conduits bridging the physical and digital realms, ensuring the seamless digital transformation of modern industries, even in the most demanding conditions.

When Supervisor perused the quarterly reports, he was elated to discover that equipment maintenance costs had plunged by 68%, and the order delivery on-time rate had skyrocketed to an impressive 99.7%. Behind these remarkable improvements stands the industrial tablet PC touch screen P10J, which has reconfigured the human-machine interaction ecosystem with its industrial-grade reliability. This tablet industrial Windows 11 device, with its rugged exterior and intelligent core, epitomizes the ongoing evolution of Chinese manufacturing within the industrial domain. As a industrial panel PC Windows 11 solution operating in demanding environments, it serves as a prime example of how industrial monitors are spearheading innovation and efficiency in industrial operations.