When selecting an industrial tablet for use in demanding industrial environments, there are several key factors that users must consider. Let’s delve into these crucial aspects.

1. Industrial Tablets’ Ability to Handle Any Industrial Environment

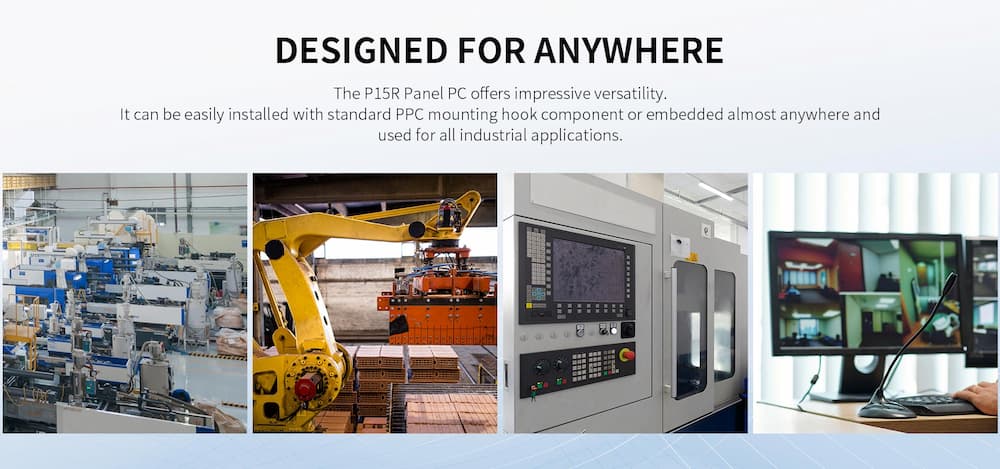

Industrial tablets are designed to be integrated into various industrial settings like production lines, robotic arms, forklift cages, and workstations. Unlike consumer-grade computers, they are built to operate in harsh conditions characterized by dust, dirt, and extreme temperatures.

These tablets boast a high IP rating, indicating their effectiveness in preventing the intrusion of foreign objects and moisture, which is essential for the durability and longevity of the device in challenging environments. Additionally, many of these tablets feature fanless heat sink designs to protect internal components from particulate matter and efficiently dissipate heat, enabling them to operate across a wide temperature range.

2. Diverse Operating System Compatibility in Industrial Tablets

Industrial tablet PCs are not limited to current operating systems and are designed to accommodate future upgrades. This versatility is crucial for ensuring the device's longevity and utility. Compatibility with various operating systems like Windows Embedded, Windows Professional, Windows RT, Linux, and POS systems, along with support for the latest I/O interfaces and high-speed ports, is essential for modern industrial applications.

3. Touch Screen Design of Industrial Tablets

In industrial settings, where lighting conditions can vary dramatically, having a tablet with a high-resolution, sunlight-readable LCD or TFT screen is critical. These screens should come with features like CCFL backlights, high brightness, and wide viewing angles to ensure optimal readability under all conditions. Given that industrial operations may require screen interaction even with gloves or wet hands, the touch screens of these tablets are designed to register up to 100 million touches and respond under various conditions.

4. Mobility and Durability of Industrial Tablets

Mobility in industrial tablets encompasses more than just portability; it includes the ability to withstand the rough handling typical in industrial environments. These tablets must endure occasional drops and bumps, especially when used in high-movement areas like forklifts in material handling systems. The rugged build of these tablets ensures they can survive and function effectively in such challenging conditions.

In summary, when choosing an industrial tablet, it is crucial to consider its adaptability to harsh environments, compatibility with diverse operating systems, screen design for optimal readability and responsiveness, and its durability and mobility under rugged conditions. These factors ensure the tablet not only meets the demanding requirements of industrial applications but also provides a reliable and long-lasting solution.